Graphitization

Cocan Graphite's commitment to producing high-quality graphite materials is powered by the local hydropower sources and newly invested roof-top solar power station. These approach not only emphasizes the company's dedication to cost efficiency but also highlights its commitment to sustainability by maximizing renewable energy.

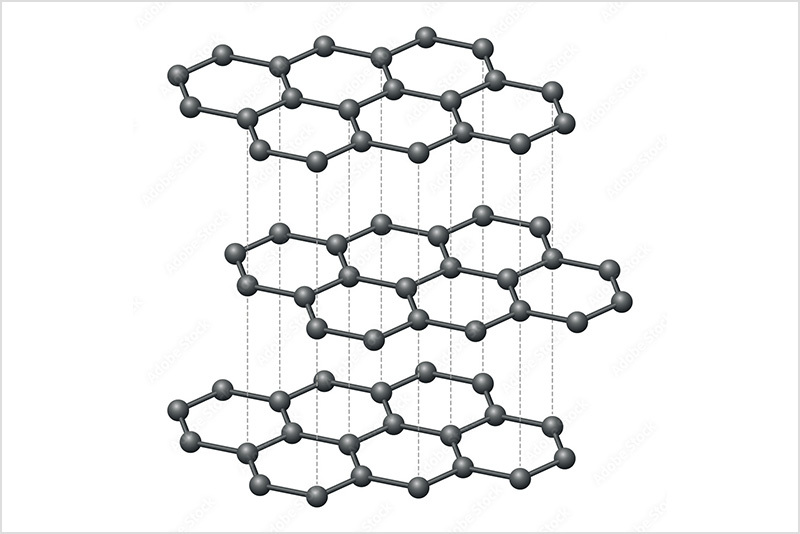

The production process at Cocan Graphite is meticulous and tailored to the specific needs of various applications. It begins with the careful selection and pre-testing of different types of carbon precursors, ensuring that each batch of raw material meets the stringent quality standards required for its intended use. These carbon precursors are subjected to temperatures reaching approximately 2800°C, where gases and impurities are progressively eliminated, and the amorphous carbon gradually converts into crystalline graphite structures.

Cocan Graphite's meticulous production and quality control ensure the creation of graphite materials with optimal properties for a wide range of industrial applications. By maintaining rigid control over every step of the process and utilizing renewable energy sources, Cocan Graphite has not only earned its reputation for consistent quality and high reliability but also demonstrates its solid commitment to environmental stewardship and cost-effective manufacturing practices.

| Capability: | Thermal treatment |

| Materials: |

Synthetic graphite, flake graphite, sponge coke, needle coke, calcined pet coke, pitch coke, etc |

| Temperature: | Up to 2800℃ |

| Results: | Different types of purity graphite per different application |

| Benefits: | Reduced ONH, metal elements, sulfur, ash, etc Increased carbon content, control of resiliency, lubrication, electrical and thermal conductivity |

Next page

Oops!

I can't find the page!

Possible reasons are:

The website may be under maintenance or there may be a program problem.

Back to Home Page